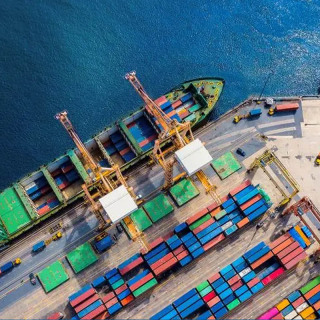

Shipping Cost From China To Usa Amazon Fba

1,Consolidate cargo from various manufacturers at origin,customs&shipping documents.

2,Offer optimum logistics solution based on clients request(Time-effevtive and Cost-effective)

How to prepare the goods for Amazon fba?

From the selection of products to determine down a product, and then to arrange FBA shipment, the first FBA shipment how much is appropriate to send?

This is the confusion of many new sellers.

there are still some sellers' questions: new products do test models, how much quantity should be sent appropriate?

We usually reply to these sellers that we never do testing.

Wouldn't that be a big loss in case of failure?

But measuring the money can be done both by actually shipping actual sales to test yourself and by a comprehensive and detailed competitor analysis. On this point, I believe that students who have read my previous article on how to screen competitors and how to conduct a detailed and quantitative analysis of competitors should have an impression.

Our point of view is that if in the process of competitive analysis found that the product is not profitable, then the product should stop here and do not do, because the current performance of the competition has reflected the failure to do profit, a product without profit, there is absolutely no need to do. If you find that the profit margin is good through competitive analysis, then the next thing to analyze is that these competing products sales, price, ranking range, etc., and then put themselves into the, "Suppose I am him, can I do his current situation? If not, how should I plan my operation strategy to achieve his current situation?" This kind of self-questioning allows us to quickly find an executable path, and then do it. The key is that, in the process of doing this all the way, the competition becomes our goal and roadmap, and the execution will be more powerful.

With this layer of analysis, it is also verified that the product can be built up, and the next issue of stocking needs to be considered from the following aspects.

First, the amount of available funds

This amount of available funds refers to both the funds needed to order the first batch of goods, but also to set aside a certain amount of money for the second batch of stock, the second and third product stock, as well as set aside a certain amount of money to pay logistics fees, other daily expenses, etc.. You can't say that only 10,000 yuan of funds all used to enter the batch of goods, tomorrow there is no money to eat, no money to pay the rent, etc..

If you must plan, the first batch of funds for stocking should account for less than 1/5 of your total capital, so as to ensure that your entire capital can flow relatively alive.

Some students will say, "But my capital is too small, only a mere 10,000, also want to split like this?

Yes, it has to be dismantled that way too.

So what products can you choose with only 2,000 dollars?

As long as you want it enough and are attentive enough, you can definitely choose the right product. For example, pick up 2 dollars of products, 2000 dollars is also enough to stock 1000 of them.

Second, available bin capacity

Own funds for stocking is one hand, and the other is that we have to see how much FBA available warehouse capacity they have. For example, a new account Amazon gives the available warehouse capacity is 1000, even if you prepare more goods, you can only send 1000 goods, then you must take this number into account.

Another point to consider is that a store often can not only do a product, if a variety of products in the creation, that each product respectively how to arrange for stocking according to the available warehouse capacity is also an element that we must consider.

Of course, we must also realize that how much warehouse capacity will change with your inventory moving rate, FBA into the warehouse shelves, efforts to move the rate of sales, both to improve their capital turnover rate, but also to improve the warehouse capacity, with more warehouse capacity, you can naturally prepare to ship more.

Third, the minimum starting weight of the headway logistics

Some sellers choose a very low unit price, very light products, the first shipment of 200, but the total weight is only a few kilograms only, in this case, the unit shipping costs are too expensive, the average to each single product, the cost of shipping is too high, so that their costs are much higher than the competition, there is no advantage.

Therefore, when shipping, the element of headway logistics cost is also taken into account.

Fourth, sales expectations

In accordance with what we talked about earlier, when you do the process of competitive analysis, the current stage of building the target to determine at a certain ranking, also know the target to reach the target when the day can be approximately how many orders, that in stocking, naturally need to follow the daily order target 30-60 times to stock. That is, assuming the current stage goal is reached, your inventory needs to be able to support sales for 1-2 months, and only so much inventory to ensure that it does not stop stocking.

Some students will have questions, so what if it is not built up? Wouldn't so much stockpiling become stagnant inventory?

Then you should make another assumption: assuming that not even one of them sells, the money used for these preparations is not enough to cause yourself to run out of the ability to take the next step. In other words, even if this batch of stockpiling fails, it will not have a fatal impact on your next development. Only such thinking is considered to have a small cost trial and error plan.